Mesin Gunting CNC Kualitas Tinggi

1. Kabeh pigura mesin diproses dening Jerman SHW pusat pangolahan pentahedron ing siji wektu.

4. Sudut shearing bisa gampang diatur liwat program supaya deformasi saka workpiece disebabake nglereni.

5. Dawane stroke balok ndhuwur bisa diatur kanthi otomatis kanggo nyadari pemotongan sing cepet lan tepat saka workpiece cendhak lan cilik supaya bisa nambah efisiensi kerja.

6. Sistem CNC bakal kanthi otomatis nyetel longkangan glathi miturut kekandelan sheet beda lan materi kanggo nambah kualitas nglereni.

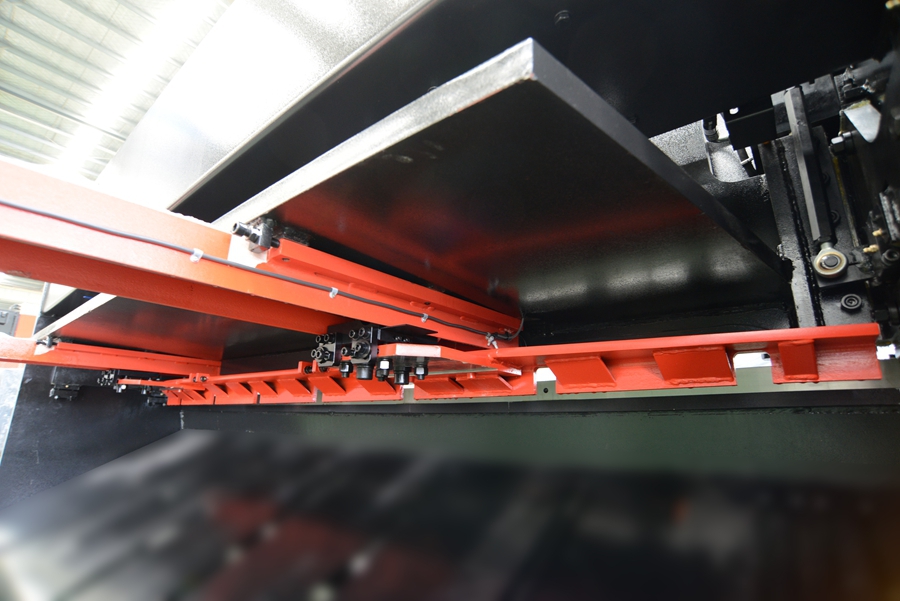

7. Four-side shearing agul-agul diadopsi kanggo nambah urip layanan saka agul-agul kang luwih apik tinimbang sing saka swing nyukur.

8, desain anyar backgauge, struktur stabil, nambah resistance Wear, crashworthiness kathah.

2. Ngadopsi sistem CNC Delem DAC360:

● sabenere kontrol backgauge

● presisi kontrol shearing stroke

● sabenere kontrol amba shearing

● presisi kontrol glathi reresik

● akurat ngontrol jumlah proyek.

3. Ngadopsi sistem hidrolik terpadu BOSCH Jerman:

● kanggo menakake pipo

●kanggo ngindhari bocor lenga

● kanggo nambah stabilitas apa

● kanggo beautify tampilan mesin

1. digunakake kanggo kontrol otomatis mesin shearing karo ngarep-dipakani lengkap-fungsi utawa backgauge

2. nganggo tampilan LCD definisi dhuwur, pemrograman jinis menu;

3. amba shearing, longkangan agul-agul, shearing stroke otomatis pitungan lan kontrol;

4. construction modul, definisi fleksibel utawa ngluwihi X1-X2 diselarasake dipakani kontrol lan tambahan Z sumbu kontrol;

5. adopts posisi Absolute lan posisi relatif programming;

6. search otomatis titik referensi, lan memori mati-posisi bisa disetel;

7. desain wheel tangan unik kanggo nggawe imbuhan mesin nduweni;

8. Antarmuka serial RS232;

9. output sinyal tambahan sing ditetepake pangguna multi;

10. program diagnosis diri;

11. panyimpenan internal 100 baris program;

12. LCD definisi dhuwur 4,7 inci;

13. fungsi program counting;

14. pilihan unit ukuran antarane sistem metrik lan sistem Inggris.

| Ora. | Item | Qty. | Cathetan |

| 1 | File Mesin | Siji set | |

| 2 | Spanner Soket Hex | Siji set | |

| 3 | Grease Gun | siji ora. | |

| 4 | Grounding Bolt | Siji set | |

| 5 | Nyetel Bolt | Siji set | |

| 6 | Kontrol sikil | siji ora. |

1. Sumber udara: priksa manawa tekanan gas sing diwenehake menyang mesin kudu luwih saka 0,6 Mpa, aliran gas kudu luwih saka 0,3 m3 / min.

2. lenga hidrolik: diimpor VG46 # lenga hydraulic anti-nyandhang. Massa lenga sing dibutuhake disetel ing ngisor iki:

| Model Mesin | Massa lenga (L) |

| VR6, VR8 seri | 230 |

| seri VRZ | 690 |

| seri VR10 | 370 |

| VR13*3200 | 460 |

| VR13*6200 | 800 |

3. Daya: 380V, 50HZ, fluktuasi tegangan ± 10%

4. Suhu lingkungan: 0°C - +40°C

5. Kelembaban lingkungan: kelembaban relatif 20-80% RH (non-kondensasi)

6. Tetep adoh saka sumber geter kuwat lan gangguan elektromagnetik

7. Lebu cilik, ora ana gas sing mbebayani utawa korosif

8. Siapke pondasi miturut gambar pondasi

9. Pilih personel relatif karo latar mburi pendidikan tartamtu kanggo noto long-term minangka operator mesin.

Mesin Gunting CNC; Gunting Guillotine Hidrolik; Mesin Gunting; Gunting cnc

2500

| Katrangan | Unit | 6*2500 | |

| Ketebalan Shearing (mm) | Baja Ringan 450Mpa | mm | 0.5-6 |

| Baja tahan karat 600Mpa | 0.5-4 | ||

| Aluminium 300 Mpa | 0.5-8 | ||

| Dawane nyukur | mm | 2500 | |

| Sudut Shearing | ° | 0,5°~2° | |

| mburi- ngukur | Stroke mm | mm | 5~1000 |

| Kacepetan mm/s | mm/s | ≤250 | |

| Akurasi mm | mm | ± 0.1 | |

| Daya Motor Servo KW | KW | 1 | |

| Stroke Times | hpm | 25-36 | |

| Kapasitas Silinder (L) | L | 230 | |

| No. saka Clamping | ora. | 12 | |

| Daya Motor Utama (KW) | KW | 11 | |

| Sistem CNC | Sistem CNC Holland Delem DAC360 ngontrol sudut geser, celah bilah, lan stroke geser | ||

| Nomer lan dawa lengen dhukungan (mm) | mm | 3*1400 | |

| Ukuran Outline | Dawane (mm) | mm | 3110 |

| Jembar (mm) | mm | 3000 | |

| Dhuwur (mm) | mm | 1705 | |

3000/3200

| Katrangan | Unit | 6*3000 | 8*3000 | 10*3000 | 13*3200 | 16*3200 | ||||

| Ketebalan Shearing (mm) | Baja Ringan 450Mpa | mm | 0.5-6 | 0.8-8 | 0.8-10 | 1-13 | 1-16 | |||

| Baja tahan karat 600Mpa | 0.5-4 | 0.8-5 | 0.8-7 | 1-8 | 1-10 | |||||

| Aluminium 300 Mpa | 0.5-8 | 0.8-10 | 0.8-12 | 1-18 | 1-20 | |||||

| Dawane nyukur | mm | 3070 | 3070 | 3070 | 3200 | 3200 | ||||

| Sudut Shearing | ° | 0,5 ° -2 ° | 0,5 ° -2 ° | 0,5 ° -2 ° | 0,5 ° -2 ° | 0,5 ° -2 ° | ||||

| mburi- ngukur | Stroke mm | mm | 5~1000 | 5~1000 | 5~1000 | 5-1000 | 5-1000 | |||

| Kacepetan mm/s | mm/s | ≤250 | ≤250 | ≤250 | 200 | 200 | ||||

| Akurasi mm | mm | ± 0.1 | ± 0.1 | ± 0.1 | ± 0.1 | ± 0.1 | ||||

| Daya Motor Servo KW | KW | 1 | 1 | 1 | 1.0 | 1.0 | ||||

| Stroke Times | hpm | 22-35 | 16-34 | 15-32 | 10-15 | 9-16 | ||||

| Kapasitas Silinder (L) | L | 230 | 230 | 370 | 460 | 460 | ||||

| No. saka Clamping | ora. | 14 | 14 | 14 | 15 | 15 | ||||

| Daya Motor Utama (KW) | KW | 11 | 15 | 22 | 30 | 37 | ||||

| Sistem CNC | Sistem CNC Holland Delem DAC360 ngontrol sudut geser, celah bilah, lan stroke geser | |||||||||

| Nomer lan dawa lengen dhukungan (mm) | mm | 3*1400 | 3*1400 | 3*1400 | 3*1000 | 3*1000 | ||||

| Ukuran Outline | Dawane (mm) | mm | 3610 | 3640 | 3720 | 4075 | 4300 | |||

| Jembar (mm) | mm | 3000 | 3000 | 3040 | 2752 | 3000 | ||||

| Dhuwur (mm) | mm | 1705 | 1755 | 1880 | 2432 | 2850 | ||||

4000

| Katrangan | Unit | 6*4000 | 8*4000 | 10*4000 | 13*4000 | 16*4000 | ||||||

| Ketebalan Shearing (mm) | Baja Ringan 450Mpa | mm | 0.5-6 | 0.8-8 | 0.8-10 | 1-13 | 1-16 | |||||

| Baja tahan karat 600Mpa | 0.5-4 | 0.8-5 | 0.8-7 | 1-8 | 1-10 | |||||||

| Aluminium 300 Mpa | 0.5-8 | 0.8-10 | 0.8-12 | 1-18 | 1-20 | |||||||

| Dawane nyukur | mm | 4070 | 4070 | 4070 | 4000 | 4000 | ||||||

| Sudut Shearing | ° | 0,5°~2° | 0,5°~2° | 0,5°~2° | 0,5 ° ~ 2,5 ° | 0,5 ° ~ 2,5 ° | ||||||

| mburi- ngukur | Stroke mm | mm | 5~1000 | 5~1000 | 5~1000 | 5-1000 | 5-1000 | |||||

| Kacepetan mm/s | mm/s | ≤250 | ≤250 | ≤250 | ≤200 | ≤200 | ||||||

| Akurasi mm | mm | ± 0.1 | ± 0.1 | ± 0.1 | ± 0.1 | ± 0.1 | ||||||

| Daya Motor Servo KW | KW | 1 | 1 | 1 | 1.0 | 1.0 | ||||||

| Stroke Times | hpm | 16~34 | 14~32 | 12~32 | 10-15 | 8-15 | ||||||

| Kapasitas Silinder (L) | L | 230 | 230 | 370 | 460 | 460 | ||||||

| No. saka Clamping | ora. | 18 | 18 | 18 | 19 | 19 | ||||||

| Daya Motor Utama (KW) | KW | 11 | 15 | 22 | 30 | 37 | ||||||

| Sistem CNC | Sistem CNC Holland Delem DAC360 ngontrol sudut geser, celah bilah, lan stroke geser | |||||||||||

| Nomer lan dawa lengen dhukungan (mm) | mm | 4*1400 | 4*1400 | 4*1400 | 4*1000 | 4*1000 | ||||||

| Ukuran Outline | Dawane (mm) | mm | 4610 | 4640 | 4720 | 4970 | 5300 | |||||

| Jembar (mm) | mm | 3000 | 3000 | 3040 | 2760 | 3000 | ||||||

| Dhuwur (mm) | mm | 1705 | 1705 | 1880 | 2562 | 2850 | ||||||

6000/6200

| Katrangan | Unit | 6*6000 | 8*6000 | 13*6200 | 16*6000 | 16*6200 | |||

| Ketebalan Shearing (mm) | Baja Ringan 450Mpa | mm | 0.5~6 | 0.8~8 | 1-13 | 1-16 | 1-16 | ||

| Baja tahan karat 600Mpa | 0.5~4 | 0.8~5 | 1-8 | 1-10 | 1-10 | ||||

| Aluminium 300 Mpa | 0,5 nganti 8 | 0.8~10 | 1-18 | 1-20 | 1-20 | ||||

| Dawane nyukur | mm | 6140 | 6140 | 6200 | 6000 | 6200 | |||

| Sudut Shearing | ° | 0,5˚-2˚ | 0,5˚-2,5˚ | 0,5˚-2,5˚ | 0,5˚-2,5˚ | 0,5˚-2˚ | |||

| mburi- ngukur | Stroke mm | mm | 5-1000 | 5-1000 | 5-1000 | 5-1000 | 5-1000 | ||

| Kacepetan mm/s | mm/s | 200 | 200 | 200 | 200 | 200 | |||

| Akurasi mm | mm | ± 0.1 | ± 0.1 | ± 0.1 | ± 0.1 | ± 0.1 | |||

| Daya Motor Servo KW | KW | 1.0 | 1.0 | 1.0 | 1.5 | 2.0 | |||

| Stroke Times | hpm | 12~20 | 12~20 | 6-10 | 5-9 | 5-9 | |||

| Kapasitas Silinder (L) | L | 690 | 690 | 800 | 800 | 800 | |||

| No. saka Clamping | ora. | 29 | 29 | 27 | 27 | 27 | |||

| Daya Motor Utama (KW) | KW | 11 | 15 | 30 | 37 | 37 | |||

| Sistem CNC | Sistem CNC Holland Delem DAC360 ngontrol sudut geser, celah bilah, lan stroke geser | ||||||||

| Nomer lan dawa lengen dhukungan (mm) | mm | 6*1000 | 6*1000 | 6*1000 | 6*1000 | 6*1000 | |||

| Ukuran Outline | Dawane (mm) | mm | 7055 | 7115 | 7220 | 7300 | 7500 | ||

| Jembar (mm) | mm | 2686 | 2690 | 2945 | 3000 | 3000 | |||

| Dhuwur (mm) | mm | 2495 | 2680 | 2850 | 2850 | 2850 | |||

Seri VR (Z):

| Ora. | jeneng | Model | Merk |

| 1 | Sistem CNC | Sistem CNC DAC360 | Holland Delem |

| 2 | Motor Servo Kab | EMJ-10APB22 | Estun |

| 3 | Servo Driver | RONET-E-10A-AMA | Estun |

| 4 | Sistem Hidrolik | Set katup hidrolik elektro-servo | Jerman Bosch-Rexroth |

| a. katup tekanan proporsional | |||

| b. katup kartrij | |||

| c. katup pemilih elektromagnetik | |||

| d. katup tekanan overlay | |||

| e. kontrol hidrolik katup siji arah | |||

| f. katup throttle | |||

| e. katup siji arah lsp. | |||

| 5 | Pandhuan linear | HSR25A-1240L | THK utawa PMI |

| 6 | Ballscrew | 25/20-1400mm | THK utawa PMI |

| 7 | Pompa lenga | IPH-5B-50-11 utawa PGH4-3X/050-E11VU2 | Jepang NACHI pump utawa Jerman Rexroth |

| 8 | Set lengkap ring sealing ing silinder lenga | USA PARKER | USA PARKER |

| 9 | Set lengkap pipa tekanan tinggi | 1.F372C91C161608-1200mm | USA PARKER, EO-2 pipe joint utawa Jerman VOSS pipe joint |

| 2.F372C91C161608-1950mm(2950mm) | |||

| 3.F381CACF151508-1480mm | |||

| 4.F381CFCF151508-2140mm(3140mm) | |||

| 5.F451TCCACF121206-1600mm | |||

| 6.F3720C19201612-1300mm Utawa F3720C1C202512-1300mm | |||

| 7.GE12ZLREDCF | |||

| 8.GE16SREDOMDCF | |||

| 9.GE42ZLREDCF lsp. | |||

| 10 | Kopling | R38 25.385/42 lsp. | Jerman KTR |

| 11 | Kontaktor AC | LC1-D38B7C, LC1-D25B7Cetc. | Schneider |

| 12 | Ngalih jarak | TP-SM5P2 etc. | TEND |

| 13 | Terminal timbal | TB2.5B TB16ICH lsp. | Phoenix |

| 14 | Tombol | XB2-BVB3LC lsp. | Schneider |

| 15 | lukisan | KAILEDI |

Seri VR (Z):

| Ora. | jeneng | Model | Merk |

| 1 | Sistem CNC | Sistem CNC DAC360 | Holland Delem |

| 2 | Motor Servo Kab | EMJ-10APB22 | Estun |

| 3 | Servo Driver | RONET-E-10A-AMA | Estun |

| 4 | Sistem Hidrolik | Set katup hidrolik elektro-servo | Jerman Bosch-Rexroth |

| a. katup tekanan proporsional | |||

| b. katup kartrij | |||

| c. katup pemilih elektromagnetik | |||

| d. katup tekanan overlay | |||

| e. kontrol hidrolik katup siji arah | |||

| f. katup throttle | |||

| e. katup siji arah lsp. | |||

| 5 | Pandhuan linear | HSR25A-1240L | THK utawa PMI |

| 6 | Ballscrew | 25/20-1400mm | THK utawa PMI |

| 7 | Pompa lenga | IPH-5B-50-11 utawa PGH4-3X/050-E11VU2 | Jepang NACHI pump utawa Jerman Rexroth |

| 8 | Set lengkap ring sealing ing silinder lenga | USA PARKER | USA PARKER |

| 9 | Set lengkap pipa tekanan tinggi | 1.F372C91C161608-1200mm | USA PARKER, EO-2 pipe joint utawa Jerman VOSS pipe joint |

| 2.F372C91C161608-1950mm(2950mm) | |||

| 3.F381CACF151508-1480mm | |||

| 4.F381CFCF151508-2140mm(3140mm) | |||

| 5.F451TCCACF121206-1600mm | |||

| 6.F3720C19201612-1300mm Utawa F3720C1C202512-1300mm | |||

| 7.GE12ZLREDCF | |||

| 8.GE16SREDOMDCF | |||

| 9.GE42ZLREDCF lsp. | |||

| 10 | Kopling | R38 25.385/42 lsp. | Jerman KTR |

| 11 | Kontaktor AC | LC1-D38B7C, LC1-D25B7Cetc. | Schneider |

| 12 | Ngalih jarak | TP-SM5P2 etc. | TEND |

| 13 | Terminal timbal | TB2.5B TB16ICH lsp. | Phoenix |

| 14 | Tombol | XB2-BVB3LC lsp. | Schneider |

| 15 | lukisan | KAILEDI |